Traditional processes in Textile, Clothing, Leather & Footwear Manufacturing can lead to inefficiencies, missed deadlines, and quality issues. These problems often result in increased production costs and lost revenue. With the absence of digital automation, manufacturers struggle to keep up with the ever-changing consumer demands and fast-paced production schedules.

In order to overcome the challenges faced in the textile, clothing, leather, and footwear manufacturing industry, companies need to implement digital solutions that can eliminate manual processes, reduce paperwork, and provide real-time insights into production data. By adopting Industry 4.0 technologies such as automation, ML, and AI, companies can improve their OEE, reduce downtime, and enhance overall quality. This modernization will attract younger talent, streamline operations, and accelerate progress toward a more digitally mature and smart industry.

Upgrade operations from analog to digital with smart apps that digitize workflows, simplify communication, and enable effective collaboration, ensuring business stays ahead in today's fast-paced digital and modern MES landscapes

Embrace digitalization, advanced MES analytics, and innovative technologies to optimize operations, and accelerate time-to-market.

Embrace the digital transformative potential of cloud and industrial technology, allowing the digitization of manufacturing.

With our MES, challenge the status quo by critically assessing production processes, and identifying areas for improvement.

Experiment with data-driven approaches, leveraging real-time analytics and machine learning, to gain actionable insights.

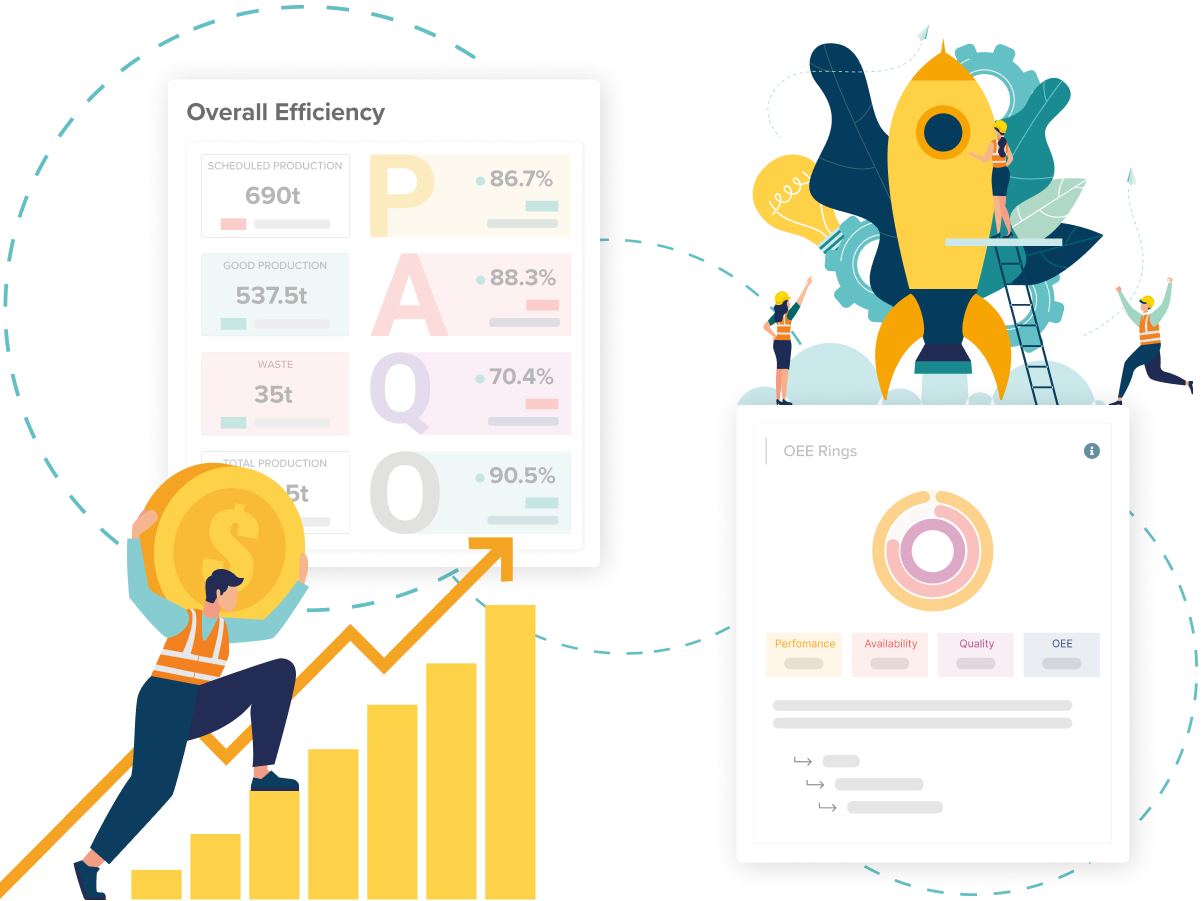

Our MES increases your overall efficiency by optimizing performance, availability, and quality parameters. Empower your operations with strategies and tools that maximize productivity, uptime, and product excellence.

Achieve better control and monitoring of your production lines with advanced MES techniques and tools.

With the MES, visualize data, identify patterns, and drive operational excellence across the production lines.

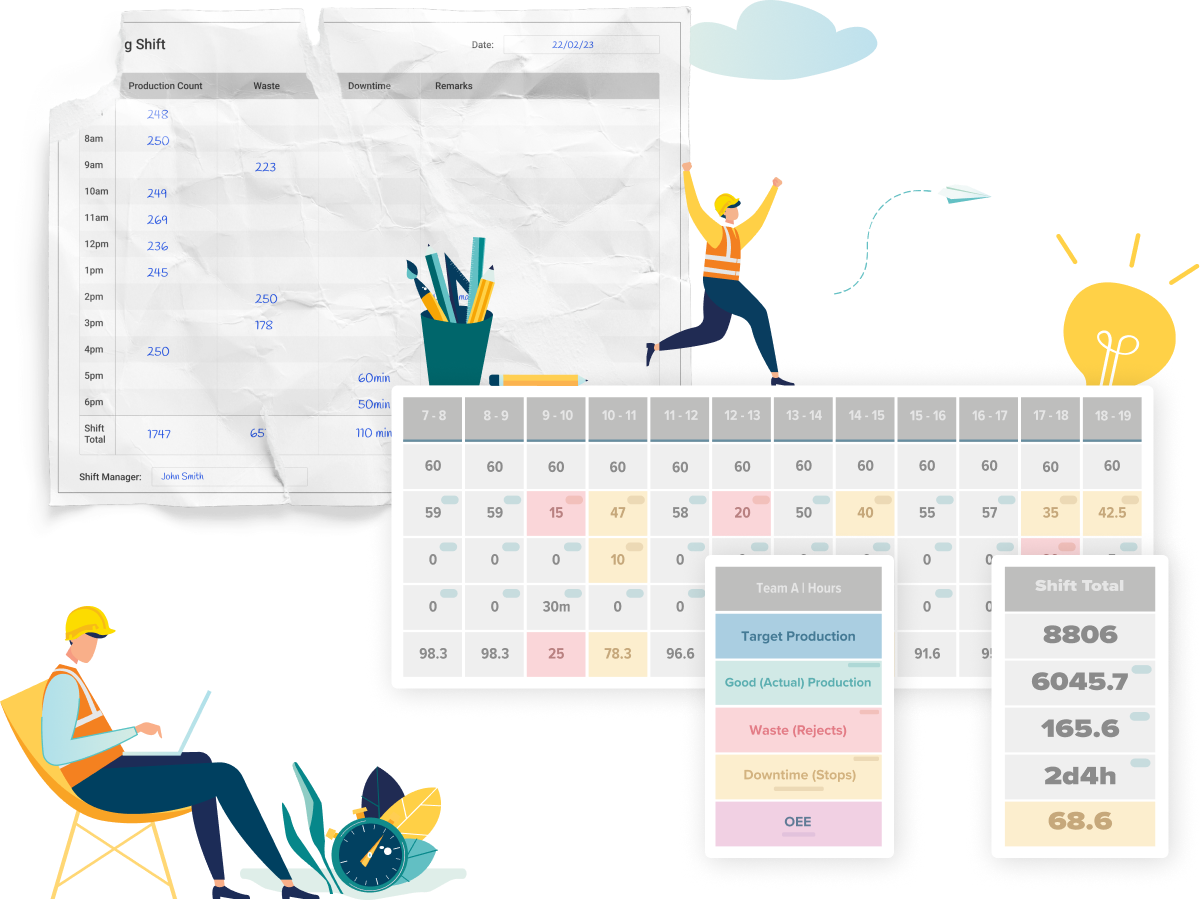

Enable real-time production pacing and scheduling on the shopfloor with an intuitive modern MES digital board.

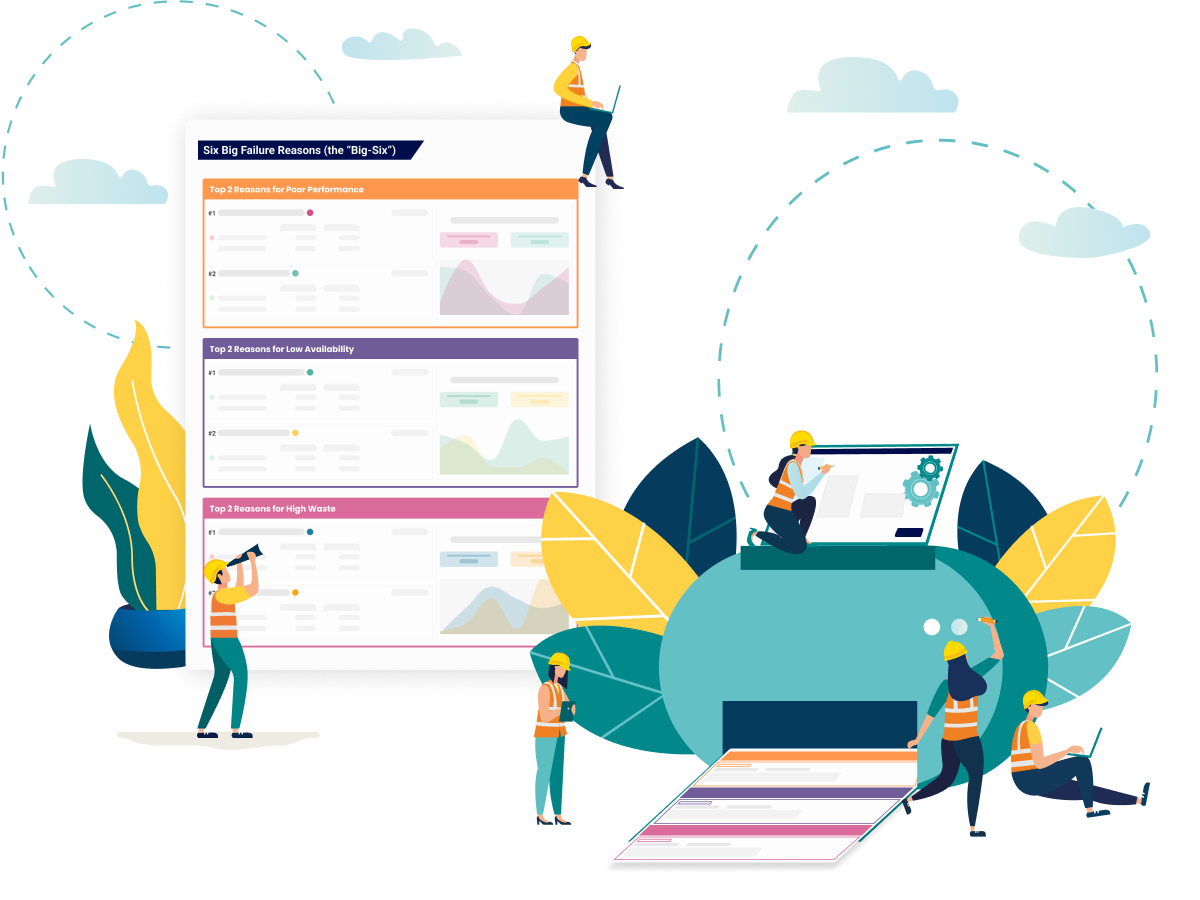

Detect failure patterns, resolve issues, and drive continuous improvement for enhanced reliability in digital dashboards.

Stay ahead of the curve in talent acquisition by leveraging next-generation MES technology. Provide a seamless, paperless digital manufacturing experience that resonates with the younger workforce.

Transform your operations by eliminating paper-based workflows. Embrace the modern MES digital-first approach for enhanced productivity.

Digital ecosystem that attracts and retains younger talent. Offer modern MES tools that upgrade work processes.

Develop a future-focused outlook with the digital MES in manufacturing. Adopt digitalization and industry advancements to achieve sustainable success.

Unlock productivity with mobile accessibility. Empower younger employees to work efficiently on their preferred devices.

Leverage MTBF, MTTR, and MTTF insights to proactively address maintenance needs and boost asset reliability. Elevate your asset management with a personalized modern or advanced MES assistant.

Empower asset management initiatives with advanced MES and actionable insights derived from robust metrics.

With our MES, measure equipment reliability using MTBF and drive proactive maintenance, minimize downtime.

Drive swift equipment repairs and minimize downtime with MTTR data, optimizing productivity with our digital platform.

Utilize MTTF as a key indicator to enhance maintenance strategies, improve asset reliability, and reduce costly failures.

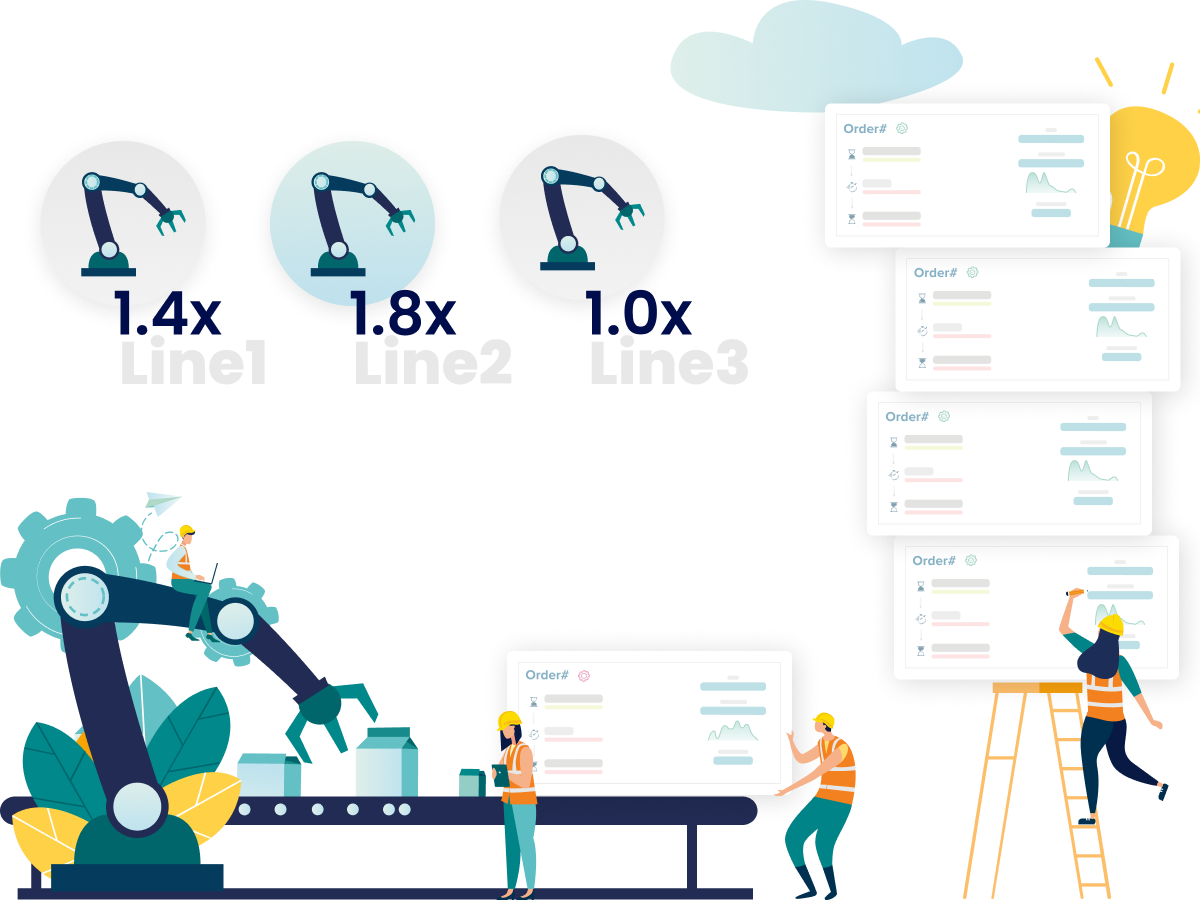

With our digital MES platform, you can enhance work order management efficiency. Our smart scheduler utilizes machine learning and AI to optimize task allocation, resulting in improved productivity.

Maximize work order scheduling effectiveness through data-driven decision-making, optimizing resource utilization.

Enhance productivity through flexible work order visualization, enabling efficient task tracking and optimized operations.

Work order scheduling with ease, leveraging data-driven strategies to enhance productivity by adopting our MES.

Connect work order management with our digital platform, update processes and enhance efficiency.

Seamlessly manage maintenance activities with our efficient planning and scheduling solution, enabling streamlined operations, improved resource allocation, and enhanced maintenance outcomes with our MES platform.

Drive efficient maintenance operations with visual planning capabilities, optimizing workflow management and improving productivity in our MES.

Maximize efficiency with Gantt & Calendar views, simplifying work order management in our modern MES.

Enhance productivity with effortless recurring maintenance planning with our MES platform.

Ensuring prompt resolution and minimizing operational disruptions of maintenance with MES.

Enhance operational visibility and performance with automated and real-time reports, enabling data-driven insights, prompt issue resolution, and effective resource optimization in your Textile, Clothing ,Leather & Footwear manufacturing industry.

Say goodbye to paperwork and whiteboards, adopt automated reports for seamless operations and enhanced productivity.

Drive efficiency in manufacturing through automated reporting, enabling data-driven optimization.

Drive organizational agility with paperless tools tailored for business transformation leaders, accelerating results.

Maximize financial visibility and control with advanced reporting tools tailored for financial executive's needs.

Unlock the power of collaboration with a central data hub, enabling teams to access real-time information, drive synergy, and achieve shared goals with our digital transformation platform.

Enable data flow and knowledge sharing across departments, breaking down data silos to foster collaboration and innovation.

Promote efficient collaboration with digital solutions that facilitate, task assignment, and real-time updates.

Eliminate the information silos and promote inclusivity by offering a solution that enables seamless data sharing.

Drive continuous improvement and employee engagement with a feedback loop that values and acts on input.

Empower your organization with data-driven insights derived from your manufacturing data, guiding you towards optimized operations and growth with our digital manufacturing platform.

Drive innovation and competitiveness through data-informed manufacturing decisions and strategies with our MES.

Investigate root causes of production deviations with our MES platform to implement preventive measures.

Track production trends to identify emerging market demands and adapt manufacturing strategies accordingly.

Drive profitability by optimizing costs across the value chain, fostering a culture of cost consciousness and efficiency.

Benefit from a fully customizable IfElseCloud MES platform that enables you to align it with your organization's branding, locale, and workflow preferences.

Modify the MES platform to match your unique manufacturing processes, enabling you to achieve precise control and quality assurance.

Evaluate key performance indicators to optimize processes, reduce waste, and increase productivity.

Customize the IfElseCloud platform to align with your brand image and language preferences.

Accurately capture equipment specifications, enabling effective maintenance planning and cost control.

120+

Real-time visibility fosters collaboration, enabling teams to work together efficiently in data acquisition and entry, and helps solve the lack of real-time data visibility challenge.

Seamlessly integrates and transforms data from various sources, ensuring uniformity and accuracy in data representation.

IfElseCloud enables real-time data streaming, ensuring the timely availability of data across systems and these digital changes helps in breaking down silos.

IfElseCloud logs user activities, facilitating traceability of actions performed on data.

IfElseCloud's monitoring capabilities enable organizations to identify bottlenecks and inefficiencies, facilitating production process optimization.

Our MES promotes agile manufacturing practices, such as flexible production lines and modular processes, to respond quickly to demand changes.

IfElseCloud's supply chain management capabilities help organizations optimize material flow and reduce inefficiencies in production processes.

IfElseCloud's customizable dashboard enables industries to monitor and manage production processes in real-time, identifying bottlenecks and inefficiencies quickly.

Our mobile maintenance features enable maintenance teams to access work orders and maintenance tasks remotely, improving response times.

IfElseCloud visualizes the production flow, enabling a clear understanding of bottlenecks and their impact on overall efficiency.

IfElseCloud's continuous monitoring features enable organizations to identify and address waste and scrap issues in real time, reducing production losses.

IfElseCloud compares production costs over time, facilitating trend analysis and identifying cost-saving opportunities, which helps solve the inability to track production costs.

IfElseCloud empowers employees by giving them autonomy and decision-making authority, fostering a sense of ownership and engagement, which helps to solve the loss of competitiveness.

Our MES capabilities enable industries to monitor and manage employer reviews, and attraction of skilled workforce.

Our MES enables industries to provide employees with open and effective communication channels and feedback opportunities and retains an experienced workforce.

IfElseCloud's proactive bottleneck detection capabilities enable organizations to detect bottlenecks before they occur, enhancing process efficiency.

IfElseCloud enables industries to manage change effectively across departments, enhancing collaboration.

Our performance analytics identifies bottlenecks, enabling workload optimization and reducing high manual labor costs.

Our MES process optimization enables organizations to optimize production processes and track production costs accurately.

Our automated reportings enable industries to generate reports quickly and make informed decisions, enhancing decision-making speed.

Solution for Shopfloor Workforce

Top Values for Managers

Strategic Solution for Executives

Read more about how various teams in your manufacturing can be benefited by adopting a modern Manufacturing Execution System (MES)

See all digital manufacturing prospects for your entire workforce.

Our tailored solutions for the Textile, Clothing, Leather & Footwear industry digitalize your processes and increase efficiency, providing you with a competitive edge.

Contact us to learn how we can benefit your Textile, Clothing, Leather & Footwear manufacturing operations.